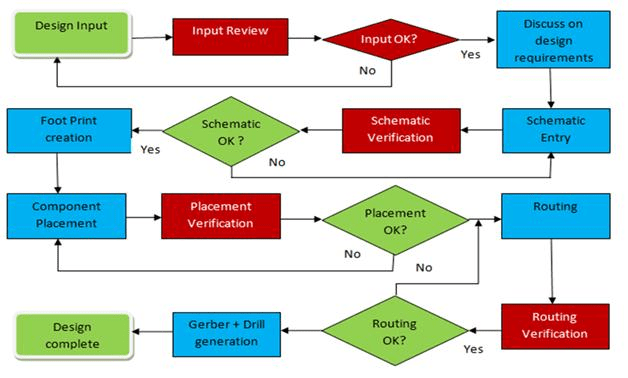

Let’s go through a brief description of all the steps involved in the process of PCB designing Part -2

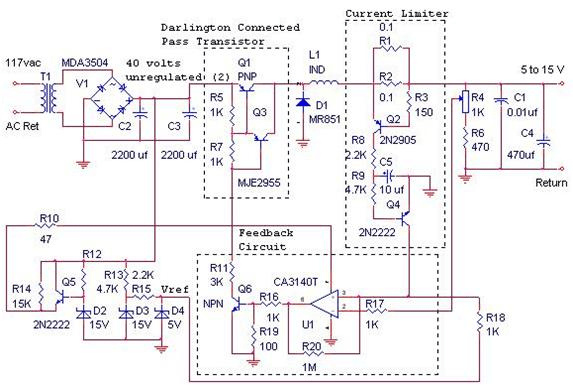

Schematic capture:

The first thing involved in preparing the design is its schematic circuit capture. For that purpose, you need to enter the circuits into a schematic editor, place the electrical components in the schematic and establish the net connections.

Netlist:

Once you’ve completed the schematic capture, you move on to convert the electronic design of the circuit to netlist (the interconnectivity information between the pins of the components). Almost all the CAD systems tend to generate the netlist from the schematics.

Netlist Verification:

The netlist file is critical to PCB function. Hence netlist verification is very important. So with netlist verified, you are sure that the entered schematic in the schematic editor is correct. Moreover, it also prevents the board from being scrapped.

PCB Design:

Before starting work on the PCB design, you need to consider the mechanical and electrical requirement of the PCB.

PCB designing involves many other steps that require execution in the following order:

- Create board outline

- Place mounting holes

- Create cutouts and keep-outs

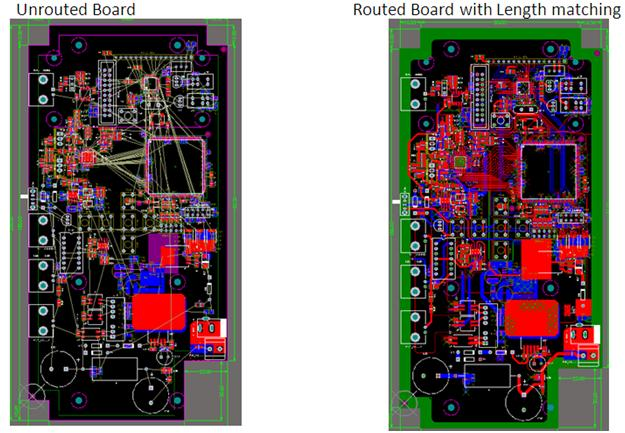

- Component placement

- Set PCB design rules

- Import netlist

- Routing the board

Create the outline of the board such that the mounting holes are of correct diameters and are precisely placed. Create cutouts and keep-outs in such a way that the correct components and signals are routed within them.

The components such as connectors, switches, LCDs, diplays, etc are to be placed such that they meet the requirements and constraint of the target application, at the same time avoiding keep-outs, cutouts and holes.

Ensure that resistors of equal value are placed in groups – diodes and capacitors be placed with their cathodes/poles pointing to the same direction. This enables an assembling that is faster cheaper and almost free from errors.

Before you begin with the routing you need to set PCB design rules supported by your manufacturer. For this purpose you need to follow the link: http://www.pcbpower.com/technical-capabilities

Routing refers to the connecting of the components placed on the board. You can draw vertical traces on one side and horizontal traces on the other which will facilitate wiring of lines crossing over the others. For multiple layers, you need to alternate between directions.

PCB Design verification / PCB DFM:

Implement design rules followed by a check and verification. You need to run DRC from time to time before finally generating CAM files! Complete a design rule check to ensure that all the design rules have been followed during the designing.

Gerber file and NC file o/p:

While generating CAM files you need to make sure that:

- All required layers are output in Gerber format RS274X.

- The drill o/p is given in excellent format

- The layers exported into the respective gerber file are correct

- Information given for plated and non-plated drills is clear – either in readme file or in the tool list file.

- All layers are on the same offset. There is no mirror layer and all layers are viewed from top side

Finalize data package for fabrication:

While preparing Data package for fabrication following points must be taken care of:

- Data package must include fabrication parameters such as: (As each design can be unique it may require additional parameters.)

- Part Number

- Revision

- Layers

- PCB size

- Thickness

- PCB thickness tolerance is usually +/- 10% unless otherwise specified.

- Copper

- Material

- Soldermask requirement

- Silk-screen requirement

- Surface finish

- Data packageshould also include following data:

– PCB Layout data

All copper layer

Solder mask files for outer layers if required

Silk-screen file for top and bottom layer if required

Board outline

Peelable solder mask, Carbon pad layers, etc. if required

– NC drill data

– Fabrication drawing or Mechanical drawing

For more details follow the link: http://www.pcbpower.com/require-input-pcb-fab.