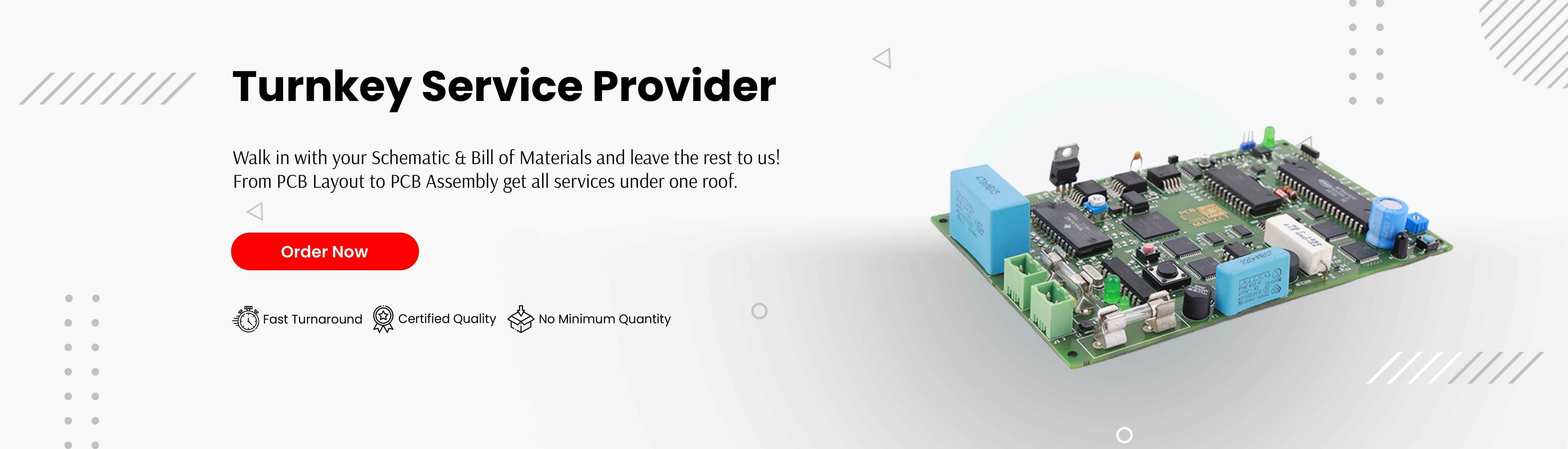

Customer Centricity

Our services, product solutions and innovations are designed around the inherent needs of our customers.

We build and help in building PCBs that empower our customers, who work round the clock to make the world a better place.

.jpg)

.jpg)

.jpg)

.jpg)